Ambition Automated: The Future of Fulfillment is Here

Are you attending LogiMat 2025? Let’s talk about the #1 challenge in logistics—labor.

- 🔷 AI-powered Robotic Picking, Robotic Sortation, and Put Walls

- 🔷 Maximum SKU flexibility – Handle irregular, oversized, and hard-to-pick items others can’t

- 🔷 Proven enterprise scale – Over 100 million picks during peak for the world’s top brands

- 🔷 Seamless integration – Works in brownfield and greenfield warehouses

What does this mean for you?

- ✅ Autonomous Fulfillment – No need for constant human oversight

- ✅ Fewer exceptions – AI-driven robots reduce manual handling and tackle edge cases with ease, lowering labor requirements

- ✅ Scalable growth – Automation that evolves with your business, adapting to changing demands

- ✅ Reliable technology – Proven beyond labs and marketing videos, trusted by the industry’s biggest players

- ✅ Smarter over time – AI-driven systems self-learn and optimize from day one

- Integrating robotics into your operations increases efficiency, flexibility, and scalability—and we’re here to make it happen. 📍

📅 March 11-13, 2025 | 📍 Stuttgart, Germany

Why Visit Booth #1GA31?

Experience warehouse simulations for sortation and our V3 Robotic Put Wall to see how Berkshire Grey robotics can reduce your labor needs by up to 50%.

Enjoy a coffee and watch our robots pick unassisted with industry-leading SKU coverage.

Stand 1GA31 | March 11-13, 2025

Stuttgart, Germany

Ambition Automated: The Future of Fulfillment is Here

Join us at LogiMat 2025 to see how we're redefining warehouse automation at Stand 1GA31.

AI-powered – Robotic picking, sortation, and put walls

Maximum SKU flexibility – Handle irregular, oversized, and hard-to-pick items others can’t

Proven enterprise scale – Over 100 million picks during peak for the world’s top brands

Seamless integration – Works in brownfield and greenfield warehouses

Let's connect! Book a meeting to explore how we can help your business scale smarter.

Redefine Productivity

4X+ THROUGHPUT INCREASES

Cost

Efficiency

SEAMLESS

INTEGRATION

Whether greenfield or brownfield, our solutions integrate without disrupting your operations.

“Berkshire Grey is the only solution we’ve seen that continually learns and improves performance over time.”

— Top 25 Global Retailer

Our solutions power some of the world’s most recognized retailers and logistics providers.

Trusted by Top Global Brands

Trusted By Top Global Brands

See It in Action at Booth #1GA31

Meet with our experts and explore how Berkshire Grey can transform your fulfillment operations.

Not attending LogiMAT? We’d still love to connect virtually to discuss your goals.

Why Choose Berkshire Grey?

Proven Results: Boost productivity and cut costs with solutions designed to deliver faster ROI and long-term value.

Scalable Solutions: Integrate into any warehouse setup without downtime.

Future-Proof Technology: Continuous learning ensures peak performance over time.

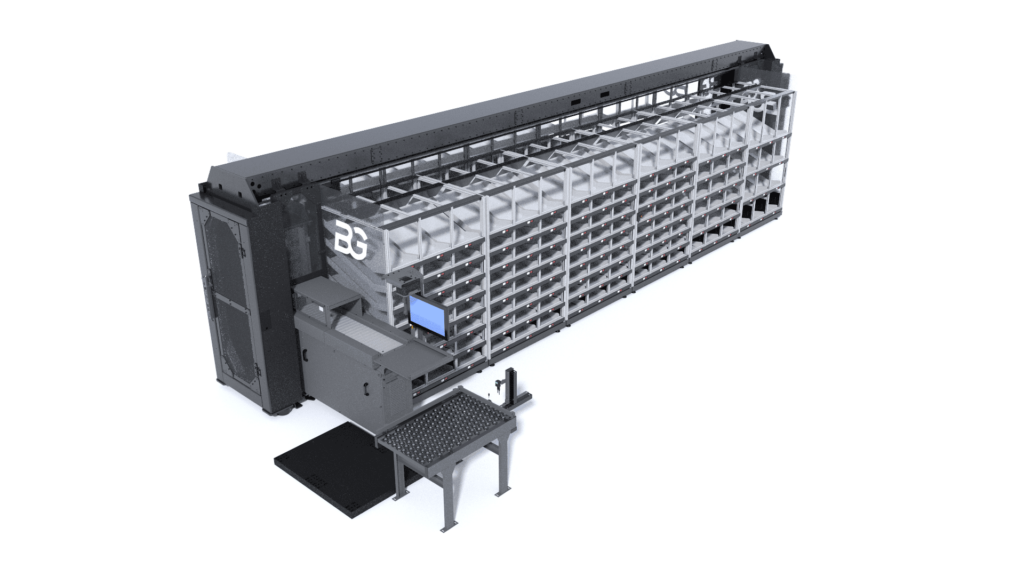

BG Put Wall

The Automated Put Wall from Berkshire Grey, powered by advanced AI-enabled robotics, elevates automated eCommerce order consolidation and returns processing. Replacing manual put walls and traditional linear sorters, the Put Wall integrates seamlessly with complementary technology to maximize warehouse efficiency.

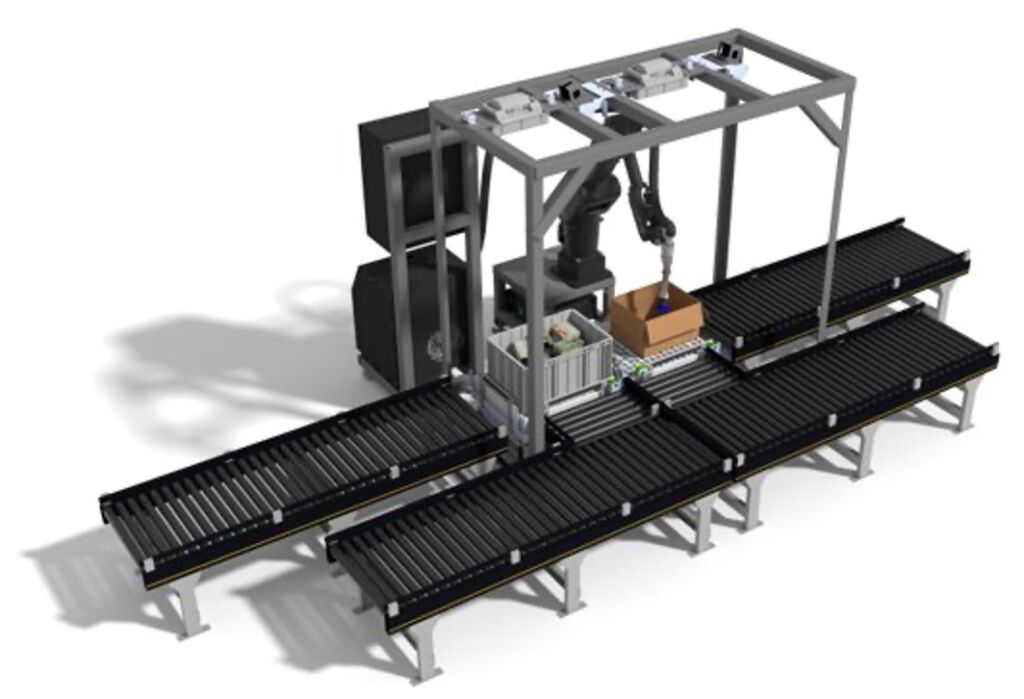

Universal Pick Cell

Picks and places into outbound conveyors, autobaggers, or auto-boxers. Perfect for bin-to-bin transfers or auto-inductions.

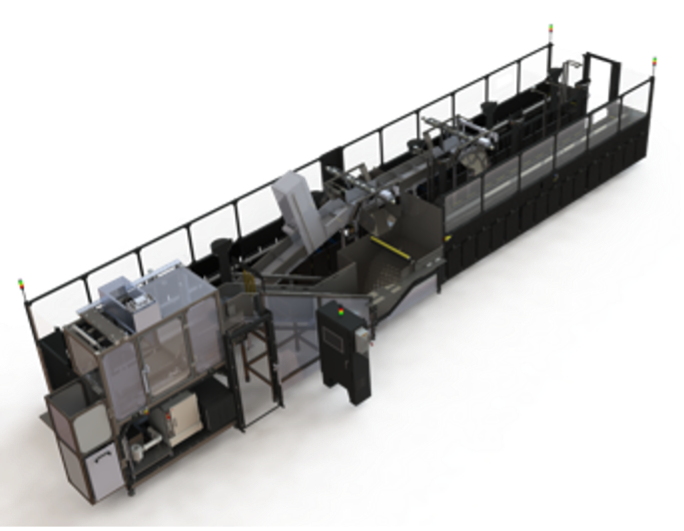

Robotic Package Sortation (RPSi)

The BG Robotic Package Sortation (RPSi) system efficiently handles large volumes of packages with ease. Using Hyperscanner™ technology, it reads and processes complex package types autonomously, reducing the need for human intervention. The system also features built-in management that alerts operators when orders are complete, streamlining the fulfillment process.

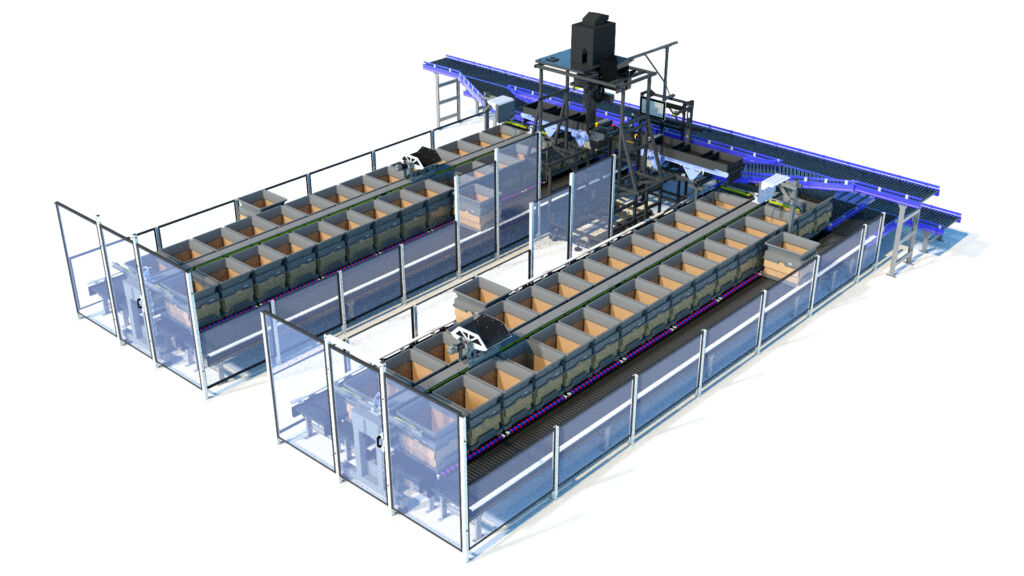

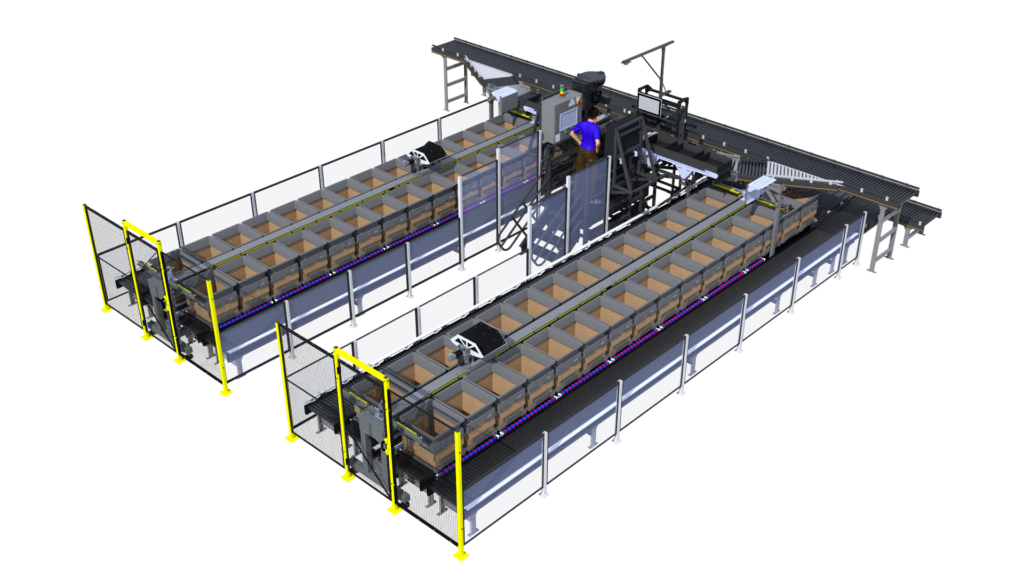

Robotic Shuttle Product Sortation (RSPS)

Automates picking, sorting, and shipping for break pack and eCommerce orders, improving order accuracy and scaling easily into existing operations. One RSPS operator matches the output of four manual sorters.

Robotic Product

Sortation (RPS)